Since 1980, Brentwood has provided industry with a range of industrial shredding machines, turn-key plants, and other associated equipment used in the processing of solid waste for reduction and recycling. Having manufactured equipment for a broad range of materials and processes, Brentwood is able to provide our customers with the benefit of many years of experience in producing machinery and turn-key plants.

To add to this, all Brentwood products are Australian made, manufactured at our plant in Unanderra, near Wollongong with some additional technology for sorting and recovery sourced from a diverse range of suppliers in Europe.

A Brief History

Jim Badman – a Chartered Engineer, formed Brentwood in 1975 to manufacture low-bed trailers. In 1977, the current Managing Director, Graham Badman – also a Chartered Engineer, joined the company as a Trainee Engineer. At that stage, the company had around 40% of the Australian market and was known throughout the industry for its expertise in both quality products and specialty design heavy trailers up to 300-ton capacity.

In 1980, the company shifted its focus to begin manufacturing of a range of industrial shredding machines. After 5 years of market and product development, Brentwood Shredders began to reach a sustainable market position. Considerable development work occurred during this period in which Brentwood has continued by expanding the range of shredder models and designing other associated materials handling systems.

In 1989, the trailer business was sold, enabling Brentwood to develop and expand the shredder business. The focus then turned to the development of various types of recycling and waste reduction plants incorporating the shredding machines, both as general purpose stand-alone products and as special projects for specific applications.

Throughout this time, Brentwood established a firm reputation with many of Australia’s leading companies and developed and installed plants and equipment in Australia and New Zealand. To add to the range of products, agency arrangements were made with some European, American & Canadian companies for the importation of machinery used in the recycling industry.

Brentwood Now

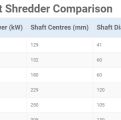

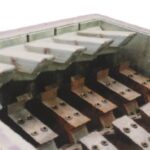

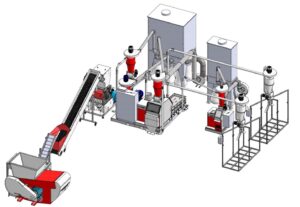

Brentwood is now headed up by Graham Badman and enjoys the reputation of being the major manufacturer of industrial shredding machines in Australia, able to offer machines up to 110 kW for all types of applications. Brentwood also offers Project Design and Manufacture in the form of Turn-Key Projects and other associated equipment used in the processing of solid waste materials for waste reduction and recycling. This includes the Brentwood range of steel plate conveyors (apron feeders), belt conveyors, bounce conveyors, and trommels which are incorporated in many of the plants built by Brentwood including Sita’s SAWT facility which was completed in 2009. The company has considerable experience in designing specialised plants for the recycling of waste materials and using the latest 3D modelling software, Brentwood Engineers are able to develop systems and machines to solve any variety of problems.

Strategic partnerships with leading European manufacturers M&J Shredders, Redox Air Separation Systems, Cushion Pack Packaging Padding Machines, Bronneberg Cable Strippers, Bronneberg Scrap Shears, Drycake Twister Organic Depackaging and Cable Granulation Plants supplement Brentwood’s range of equipment enabling Brentwood to offer our clients a full spectrum of sorting technologies.