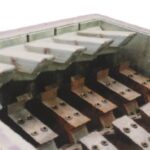

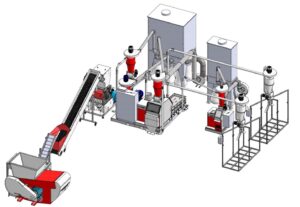

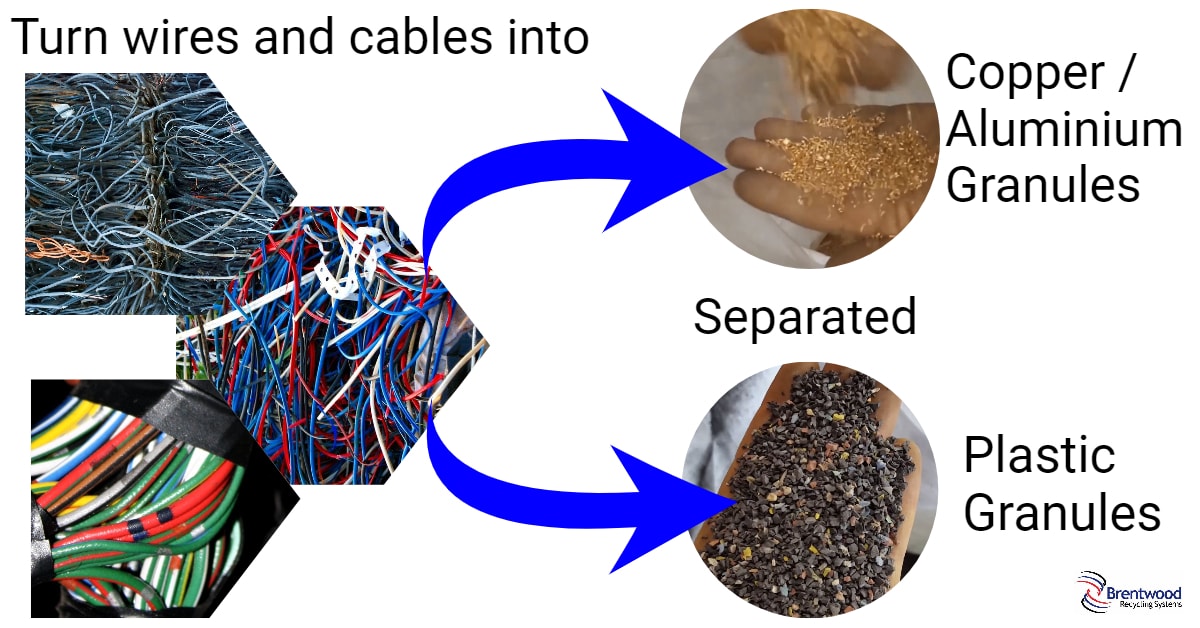

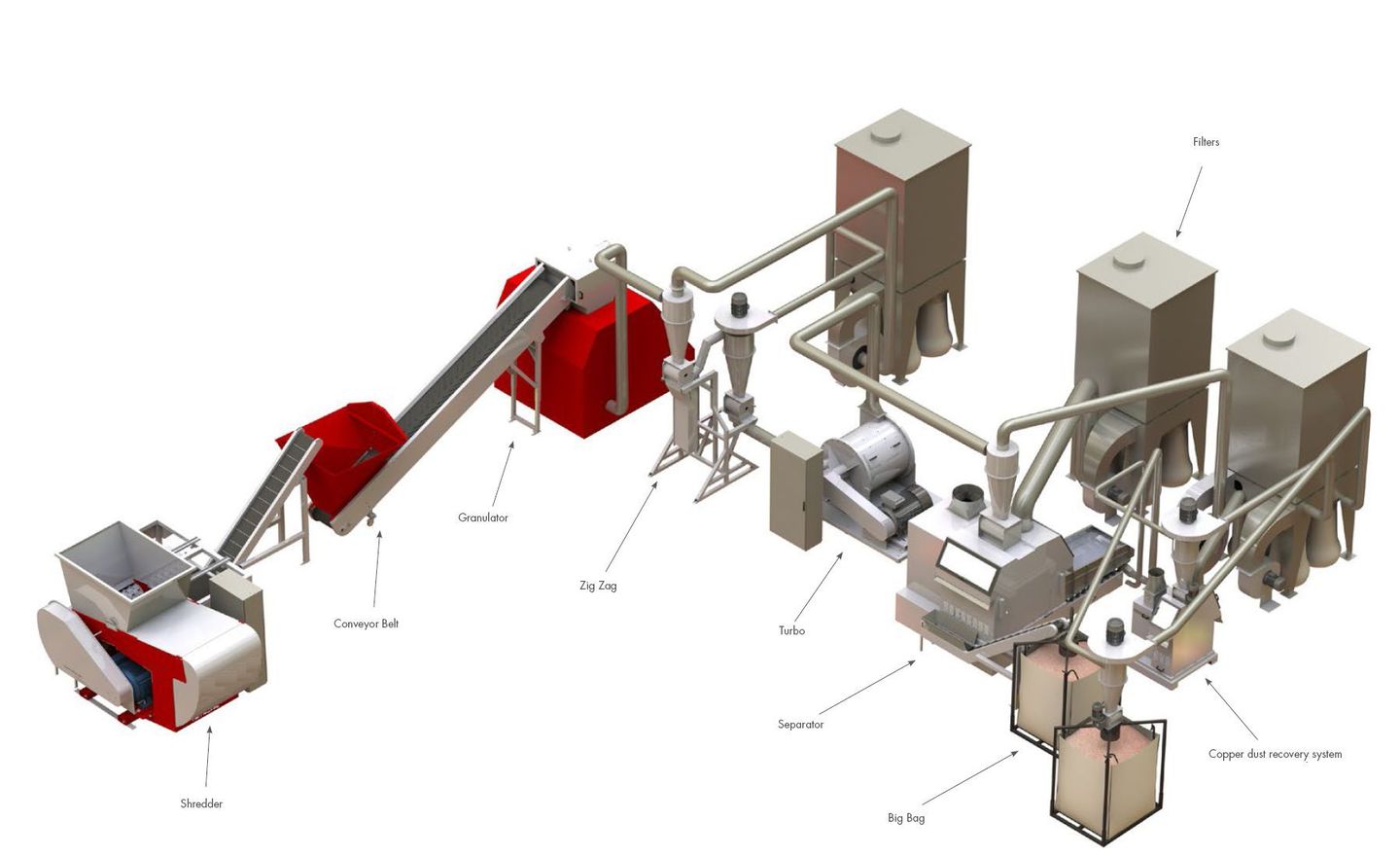

When working with higher volumes of cables, handling and loading the machines becomes more challenging. Adding an MG infeed shredder and conveyor to a cable separation machine gives it easier and faster loading. These systems help to run the machines at the optimal flow rate for the material mix and machine capacity.

Given that the MG Recycling Cable Separation Systems are designed to work as a family, this provides flexibility to add machines and functions as required. Start out with a small hand-fed multi function machine and add plant functionality to it later. Further extend its functionality with Cable Processing Accessories.

The plants are available in packages to suit different volumes of cables from 250kg/hr up to 2000kg/hr.

Plant operation can be further enhanced by adding accessory machines as desired.

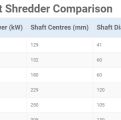

STANDARD PLANT RANGE SPECIFICATIONS

| MODEL | DESCRIPTION | MAX THROUGHPUT (kg/hr) | POWER (kW) | DIMENSIONS WxDxH (m) |

|

|---|---|---|---|---|---|

| MG 150 TR 600 | MG 150 + TR 600 Shredder and Conveyor | 250 | 40.5 | 3.0 x 4.7 x 2.8 |

| MG 220 TR 600 | MG 220 + TR 600 Shredder and Conveyor | 400 | 61 | 3.6 x 5.1 x 3.1 |

| MG 220 VZT TR 600 | MG 220 VZT + TR 600 Shredder and Conveyor | 500 | 80.5 | 3.3 x 8.9 x 4.3 |

| MG 380 VZT TR 800 | MG 380 VZT + TR 800 Shredder and Conveyor | 1000 | 139 | 3.7 x 9.1 x 4.3 |

| MG 610 VZT TR 1200 | 610 VZT + TR 1200 Shredder and Conveyor + Granulator | 2000 | 225 | 5.0 x 15.7 x 4.4 |

Custom plants with advanced accessories

For higher volumes and specific use cases, cable separation lines can be customised for your use case.