Trommels 101 : Understanding Trommel Screen Design

An understanding of the design factors for Trommel Screens is essential in the development of the correct specification for a particular application. The following details are designed to assist in this process and minimise the consequences of poor selection. these consequences could include excessive fines in the oversize fraction, insufficient production rate, inability to adapt to different materials or production rates, and screen damage.

In selecting or designing a trommel screen, the following factors need to be considered and understood:

Input Material Specification : What Goes In

Bulk density : How many Kg’s per cubic meter is the material as it enters the screen ? Trommels essentially move a volume of material, so the space a known weight of material takes up is critical to performance and the power required to do so.

Granulometry : What is the material size split of each material size that needs to be processed ? This is best expressed in weight (ie kgs) as a split by volume does not necessarily provide accurate information because the sum of the volumes of each size after separation rarely equals the input volume. This occurs because voids in the input materials can filled by smaller product without changing the total volume.

So, if the trommel is required to split a material running at 10 tonne/hr into 3 sizes say <10mm, 10-50mm and plus 50mm, the designer therefore needs to know:

| Output Stream Size | % Split | Weight Split (kg) |

|---|---|---|

| <10mm | 25% | 2,500 |

| 10-50mm | 20% | 2,000 |

| >50mm | 55% | 5,500 |

| Total | 100% | 10,000 |

Moisture Content of the Material : This provides an understanding as to how “sticky” the material may be. A material laden with excessive moisture will increase the tendency to stick to the trommel drum or inside the screen holes and then possibly blocking the screening holes. Moisture content is expressed as the percentage of water in the total weight of material (including the water).

Maximum and Average Granule Weight : This is the weight of any one item entering the screen. This is required to correctly size the screen thickness. A drum processing concrete blocks will require significantly thicker drum thickness than one processing compost or bark

Process Specifications : What Needs To Be Done

Production Rate : This is the rate of infeed material needed to be processed in any given period. Peak rates which could be experienced, become the limiting factor of the design and therefore should be understood. A processing plant may process 30t/hr as an average over an 8 hour day, however if in 15mins the material inflow could be 10 tonne, which equals 40t/hr. In this case the design production rate must be the peak rate of 40t/hr.

Trommel Specifications : What Features Can I Have

Trommel Screens can be built with a combination of the following specifications:

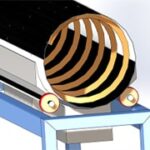

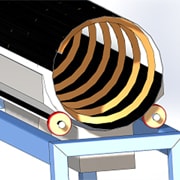

Drum With Internal Screw – Used where the drum angle is either level or a slight slope ie <5 deg. Level drums require an internal spiral to move the material through the drum. Sloped drums rely on the material moving through the drum by being rolled or lifted (by lifter bars) further down the drum each movement (or drop)

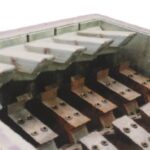

Drum With Internal Screw – Used where the drum angle is either level or a slight slope ie <5 deg. Level drums require an internal spiral to move the material through the drum. Sloped drums rely on the material moving through the drum by being rolled or lifted (by lifter bars) further down the drum each movement (or drop) Internal Lifter Bars – these aid the agitation of the material which helps separate the materials. Lifter bars also provide the lift and drop action which moves the material through the drum. Without lifter bars material rolls through the drum at a much slower rate. Typically heavy material such as C&D waste will not include lifter bars as the dropping of the material can damage the screen.

Internal Lifter Bars – these aid the agitation of the material which helps separate the materials. Lifter bars also provide the lift and drop action which moves the material through the drum. Without lifter bars material rolls through the drum at a much slower rate. Typically heavy material such as C&D waste will not include lifter bars as the dropping of the material can damage the screen. Perforated Plate Screen – Plate when rolled and welded to form the drum is significantly stronger than the typical steel skeleton with mesh attached. Rolled steel plate drums have the holes cut out of the plate and are less prone to damage from foreign objects like steel bars. Steel plate is easier to clean due to the lack of ridges (which are found in mesh designs). The lack of ridges also reduces the wear in plate screens compared to mesh.

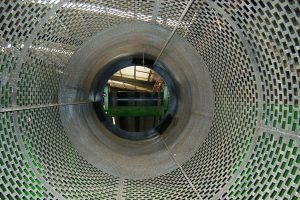

Perforated Plate Screen – Plate when rolled and welded to form the drum is significantly stronger than the typical steel skeleton with mesh attached. Rolled steel plate drums have the holes cut out of the plate and are less prone to damage from foreign objects like steel bars. Steel plate is easier to clean due to the lack of ridges (which are found in mesh designs). The lack of ridges also reduces the wear in plate screens compared to mesh. Mesh Screen Designs – this type of design is weaker than a perforated plate design and is more prone to damage and wear. For this reason, many mesh designs utilise replaceable screen sections. Cleaning is more difficult with mesh designs due to entrapment of material on mesh ridges and in broken/damaged sections of the mesh.

Mesh Screen Designs – this type of design is weaker than a perforated plate design and is more prone to damage and wear. For this reason, many mesh designs utilise replaceable screen sections. Cleaning is more difficult with mesh designs due to entrapment of material on mesh ridges and in broken/damaged sections of the mesh. Noise and Dust Suppression – The trommel can be fitted with covers to allow for dust extraction and minimisation and for noise suppression.

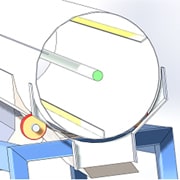

Noise and Dust Suppression – The trommel can be fitted with covers to allow for dust extraction and minimisation and for noise suppression. Drive Systems – Several drive methods are available including friction drive from the supporting wheels, chain drive using a chain wrapped and welded around the drum, or by gear drive using a gear tooth profile on the drum. This is a decision based on the amount of friction available through the support wheels for the job being done. The friction is a function of the number of drive wheels, size of drive wheels, friction coefficient of the wheels to the driven surface of the drum (in the operating condition – which may be outside in the rain). If the available friction is not achievable, then chain and gear drives must be utilised, however there are additional costs involved in these alternatives.

Drive Systems – Several drive methods are available including friction drive from the supporting wheels, chain drive using a chain wrapped and welded around the drum, or by gear drive using a gear tooth profile on the drum. This is a decision based on the amount of friction available through the support wheels for the job being done. The friction is a function of the number of drive wheels, size of drive wheels, friction coefficient of the wheels to the driven surface of the drum (in the operating condition – which may be outside in the rain). If the available friction is not achievable, then chain and gear drives must be utilised, however there are additional costs involved in these alternatives. Bag Breakers – for opening plastic bags – typically used to release materials retained in bags such as household waste which has not been shredded before screening.

Bag Breakers – for opening plastic bags – typically used to release materials retained in bags such as household waste which has not been shredded before screening. Cleaning brushes for keeping holes clean are efficient as long as the product does not contain long stringy material as this can easily clog brushes. Brushes are rarely used for very dry product as these materials do not clog holes.

Cleaning brushes for keeping holes clean are efficient as long as the product does not contain long stringy material as this can easily clog brushes. Brushes are rarely used for very dry product as these materials do not clog holes.