Custom Machines: Built to your requirements.

Sometimes a standard, off the shelf solution just doesn’t cut it. At Brentwood, we understand this and pride ourselves on our ability to customise our equipment to meet our customers exact requirements. Need a longer shredder – no problems. Got a tricky infeed/discharge requirement – we can help. We are an engineering company and can work with you to develop and build plant and equipment using our own machinery – built in our Unanderra factory, or source core technology from our overseas partners to build the plant that you need.

Below are just a few of the projects that we have designed from our customers. Ask us how we can help with your plant requirements.

Stainless Steel Washer Trommel.

Stainless Steel Washer Trommel. Product Destruction Shredding Plant.

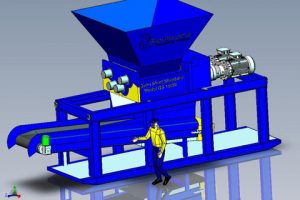

Product Destruction Shredding Plant. AZ50HD 37kW dual shaft shredder fitted with hydraulic pusher ram hopper.

AZ50HD 37kW dual shaft shredder fitted with hydraulic pusher ram hopper. QS50HD with extraction system

QS50HD with extraction system AZ50HD Pallet Shredding System.

AZ50HD Pallet Shredding System. QS50HD waste shredder with discharge to dual compactor bins.

QS50HD waste shredder with discharge to dual compactor bins. AZ5 Playing Card and Token Shredder

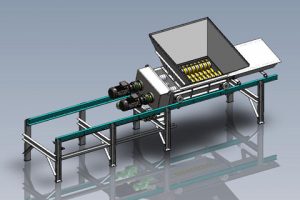

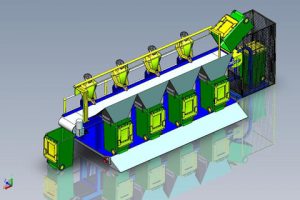

AZ5 Playing Card and Token Shredder Movable 4 man picking station.

Movable 4 man picking station.

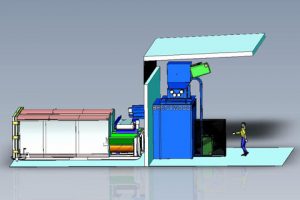

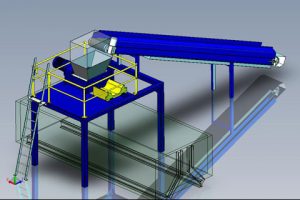

QS150W Moveable Shredding Plant

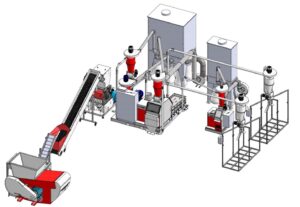

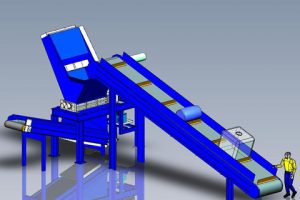

QS150W Moveable Shredding Plant Bulk Paper Shredding Plant

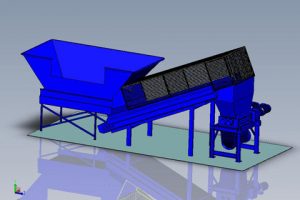

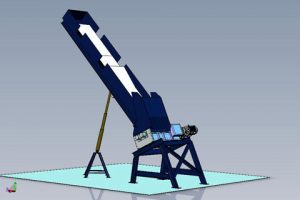

Bulk Paper Shredding Plant Tilting Chute Shredding Plant

Tilting Chute Shredding Plant IBC and Drum Shredding Plant

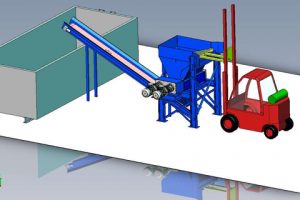

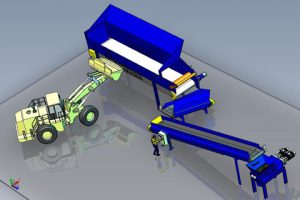

IBC and Drum Shredding Plant AZ60 Bulk Waste Feeder System.

AZ60 Bulk Waste Feeder System.