Reclaiming raw materials in old or redundant electrical cables is a complex task that involves processing material that is difficult to handle. The cables come in a wide variety of sizes, coiled up and manufactured from a mixture of valuable different materials – copper, aluminium, plastics, rubber and fabric.

Our range of quality MG Recycling Cable Separation machinery is the easy way to reclaim valuable materials. With processing capability from hand loading to bulk loading of coiled up cables, the systems can then produce a ‘waterfall’ of separated valuable materials ready-for-market.

The machinery caters for smaller volume electrical contractors through to large volume scrap recyclers and cable manufacturers.

‘Waterfall’ of Copper flowing out

How does cable separation work?

A cable separation plant use a series of processes that take whole cable coils to:

- Pre-shred

- Granulate

- Separate valuable materials using a densimetric table

- Manage dust with filtration

- Place material particles into containers for easy handling

Optional equipment is available to further:

- separate aluminium from copper

- remove fine copper particles otherwise lost to air filtering

- magnetic separation of ferrous components

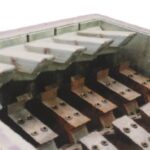

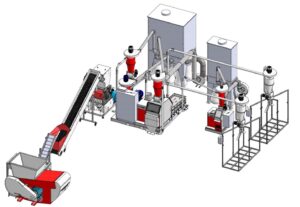

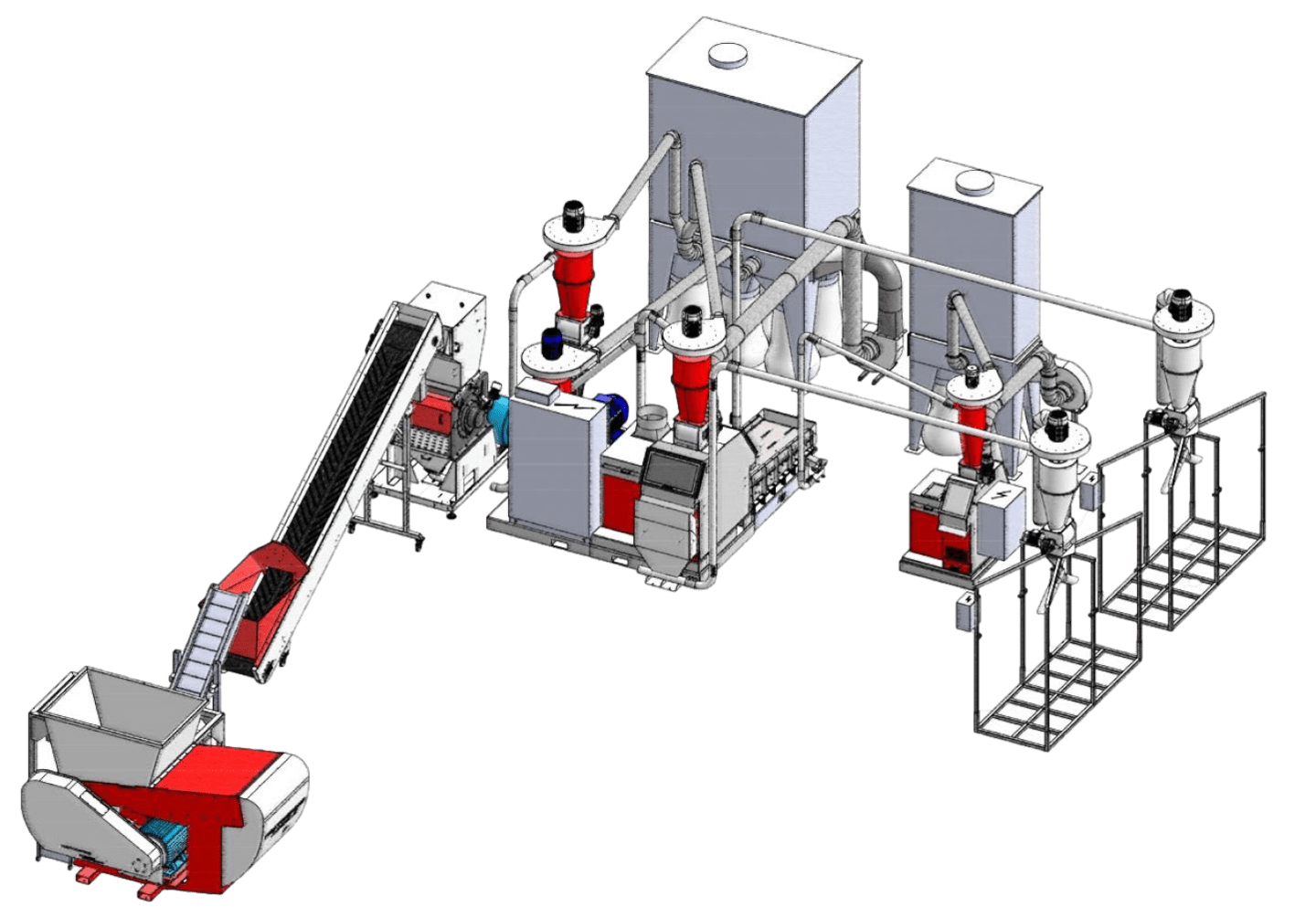

Above: MG Recycling Cable Separation plant configured with individual single-purpose machines.

A range of machines that integrate with additional functions to form plants

The MG Recycling Cable Separation range comprises machines and plants.

All MG Cable separation machines stand alone to granulate cable and provide separated metal from plastics. They include a:

- granulator

- air transport system

- vibrating densimetric table to separate metals from plastics

- dust filter

- electrical controls for all items including PLC in one cabinet

Plants provide the ability to handle coils of cable. They include:

- infeed shredder

- conveyor to take shredded material to the granulator automatically

- a ‘machine’ (as described above)

- additional electrical controls for shredder and conveyor integrated into the machine control panel

This modular design approach gives you flexibility to specify only the capabilities you need with the flexibility to expand later as needed.

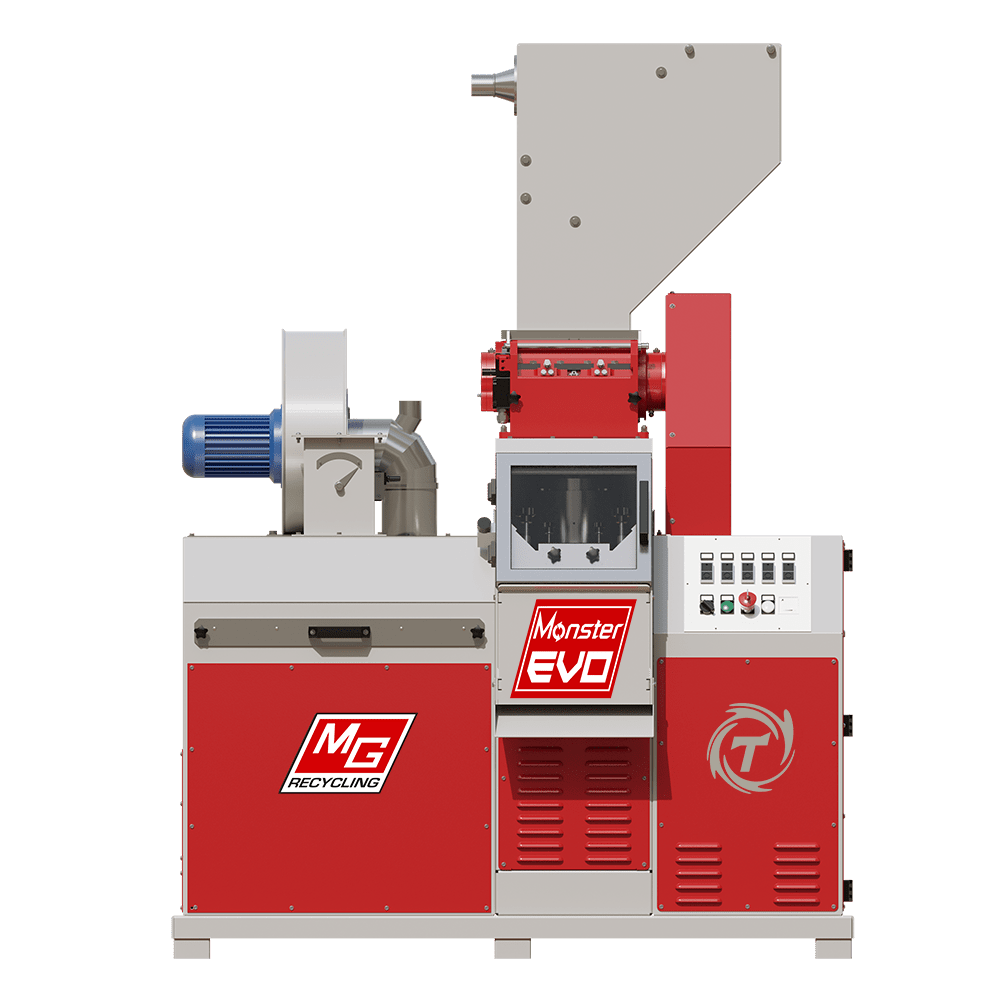

MG Cable Separation ‘Machines’ – for simplicity and scale

One of the highlights in the machine family is the range of MG Recycling Cable Separation machines. Cable separation machines combine many full-scale cable separation plant functions (granulating, separating, sorting and filtering) into one compact machine. They provide:

- Simple operation: cable in – raw materials out

- High-purity output to get best market rates for fast payback

- Metals and plastic separation

- Process up to 2000kg of cables per hour.

- Compact footprints to occupy as little space of your facility as possible

- Can be paired with other machines in the lineup for different levels of desired automation from manual hand feeding to full plant operation.

- Modular approach to suit different infeed material mixes and operational goals.

.

MG Cable Separation ‘Plants’

– for throughput and automation

When dealing with higher volumes of cables, handling and loading machines becomes more challenging. Turning a cable separation machine into a cable separation plant provides more efficient feeding so that your plant can run at the optimal flow rate.

Plants are available in a variety of popular layouts and configurations, from a small cable separation machine with shredder and conveyor all the way up to large plant line up utilising advanced separation functionality such as :

- aluminium/copper separation

- ferrous separation

- fine copper collection

MG Cable Separation Machines

Machines designed for the recovery of Copper and Aluminium from electrical cables

MG Cable Separation Plants

Popular configurations of cable separating machines with Shredders and Conveyors to Automate operation

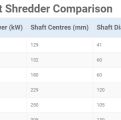

MG Infeed Shredders

Infeed Shredders designed to turn the cables into consistently sized material ready for the processing machines. Available in 3 sizes to suit different processing requirements

Cable Processing Accessories

Range of add on machines that add capabilities to your system. Capabilities include Automated Bagging, Copper-Aluminium particle separation, Copper dust recovery.