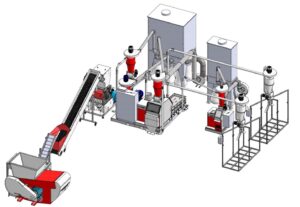

Heavy duty shredders designed for solid waste.

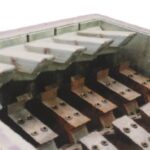

Brentwood’s broad range of heavy-duty industrial shredders are designed to be robust, efficient, and give years of trouble-free service.

Brentwood has manufactured in excess of 700 industrial shredders which are used in a diverse range of shredding applications. Typically, these machines are used in recycling, manufacturing or processing industries for waste reduction or material recovery processes.

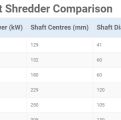

Our shredders are heavy duty machines designed for industrial applications and can be configured to efficiently process a wide range of materials. The manufacturing techniques adopted at Brentwood are of the highest standard using state of the art technology. This provides machinery with low maintenance requirements and proven reliability. Shredder designs include Single-shaft shredders, Dual-shaft shredders and Quad-shaft shredders.

The list of applications where our shredders are used is constantly growing and we look forward to expanding this list with your unique application – please contact Brentwood so we can solve your solid waste or recycling problems.