When you need a complete solution for solid waste processing ….

Brentwood can design and manufacture innovative solutions for a wide range of solid waste processing requirements. Not all solutions are “off the shelf” and this is where over 43 years of engineering experience in the solid waste industry become an invaluable asset to our customers. We will work with you to develop a solution that is based on sound engineering principles and ensures a process that is efficient, safe, and robust.

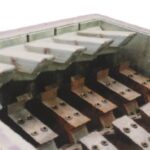

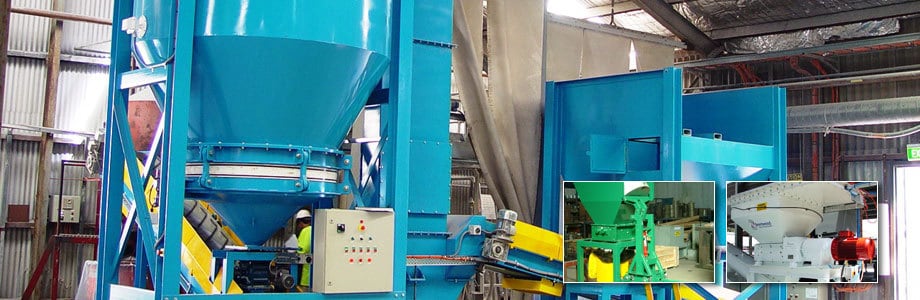

Custom Waste Equipment.

Over the years we have developed many unique solutions, often incorporating our range of shredders, conveyors, trommels, and feeders. We can customise infeed and discharge arrangements and incorporate our designs into your existing plant and equipment. Talk to us today about how we can use our experience to benefit your processes.

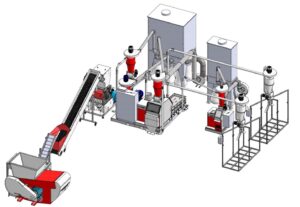

Large Plants.

We can also design and build complete waste recycling plants incorporating a wide range of core technologies.