The solution for effective and consistent sizing of bone and hard offal for abattoir and rendering applications

Single shaft hoggers have been the mainstay of abattoir and rendering operations worldwide however these machines have some significant drawbacks when compared to Brentwood Pre-Breakers.

Traditional hoggers rotate at higher speeds and have greater interface tolerances resulting in inconsistently sized particles, product emulsification, and large amounts of separated fat particles (“pea fat”) being generated and lost to the effluent system. Poor cutting efficiency and inconsistent particle size increases cooking times and can result in overcooking of the product resulting in increased fines and increased F.F.A (free fatty acids). Brentwood Pre-Breakers are high torque/slow speed machines with low interface tolerances providing a cutting action that produces consistently sized particles and a reduction in fat losses therefore improving the efficiency of downstream processes.

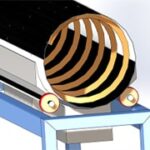

The low residence time in the cutting chamber ensures that no heating or emulsification of the product occurs. Large material such as heads and rib cages are efficiently grabbed by the counter rotating cutters and dragged towards the opposing shaft. The material is then sheared as is passes between the intermeshing cutters. The high torque/low speed design increases cutting efficiency, reduces power requirements, and reduces maintenance costs. The design of the machine is robust so that any metal items such as hooks are able to be passed through the shredder with minimal damage. Larger unshreddable items will activate the overload back off function enabling an alarm to be sent to the operator and the unshreddable item removed.

These units can be easily cleaned with a high pressure hose and the hot dipped galvanised finish ensures a long cutting chamber life. These units were developed in conjunction with the CSIRO (Commonwealth Scientific and Industrial Research organisation) to increase the efficiency of the Australian Abattoir Industry and have been proven under the most demanding conditions in hundreds of locations throughout Australia, New Zealand, and overseas. See CSIRO reports A-89 and F-85