Great advantages of modular design

The M&J P250 is the mid-sized model of the M&J PreShred stationary pre-shredder family. It can process various waste types such as bulky waste, commercial and industrial waste, municipal solid waste, construction and demolition waste, biomass, wood, as well as baled materials. The pre-shredder is generally used in refuse-derived fuel (RDF) production, biomass processing, waste-to-energy plants (WtE) and in mechanical biological treatment plants (MBT).

Excellent uptime

The M&J P250 features an open cutting table that allows stones and other hard particles like metals to fall through the cutting area. The open cutting table design and bi-directional shredding system increases safety and reduces the risk of malfunctions that may hinder operations.

All knives and parts exposed to wear on the M&J P250 are made from wear-resistant steel, ensuring continuous and long-lasting performance. Bolts and bearings are conveniently mounted away from the cutting area, allowing for easy access and maintenance to reduce costly downtime.

Intelligent performance

The M&J P250 can be adjusted to meet all waste processing requirements. Its bi-directional knife assembly runs both clockwise and anticlockwise with equal speed and torque. The shredder can change the direction of rotation when it encounters challenging materials, thus enabling self-feeding and eliminating the need for a pusher.

The pre-shredder is equipped with an intelligent control unit that automatically adjusts shredding routines to suit the processed material. The control unit has 6 standard programmes and 2 custom programmes, allowing for tailored shredding routines for maximized performance.

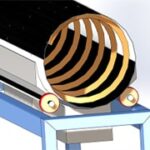

Patented modular design

The M&J P250 has a modular construction. The chassis, conveyor and oil coolers can be adapted to meet individual requirements in either new or existing plants.

The pre-shredder has a large cutting table and an aggressive heavy-duty knife assembly. The robust frame of the M&J P250 has been designed to require less power to operate, thus minimizing energy consumption without sacrificing output.

Versatile Applications

The M&J P250 is an excellent solution for even the most challenging of materials. Many different assembly options – ranging from different knife shapes to the number of knives – enable you to customize and adjust the pre-shredder to produce the required grain size for any solid waste material.