Tyre Shredding Solutions

Brentwood has been manufacturing and supplying shredding machines for processing car and truck tyres for many years. Through extensive R & D and interactive liaison with our customers, our current range offers the latest technology in tyre shredding and processing.

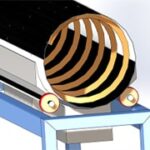

As steel radial tyres are one of the most difficult products to shred in our industrial age, particular attention has been paid to developing machinery with superior working life and low maintenance. Brentwood offers a large range of machines with many diverse cutter arrangements. This allows us to provide machinery to produce various product sizes required for primary or secondary processing. This can be achieved by cutter selection, multi shredder plants or screening.

Tyre shredding is a worldwide necessity due to environmental controls restricting the dumping of whole tyres. Innovative industries are continually using shredded tyre for purposes such as fuel for kilns, retaining wall fill, 25 – 50mm chip for road base, municipal tip cover. Extensive use of rubber chip for production of rubber crumb is now commonplace. As the charges for dumping whole tyres are increasing, new business opportunities are emerging. Fees for tyre removal are charged, which incorporates sufficient funds to allow shredding prior to further processing or disposal.

Brentwood Engineers can assist in the selection of correct machinery to suit a particular application. In determining this, the following considerations must be addressed:

- Types of tyres to be shredded – car, light truck, truck or other?

- Quantities to be shredded?

- Production rates required?

- Size of shredded product?

- Maintenance requirements?

- Power supply?

The AZ-50HD

The AZ-50HD

The AZ-150W

The AZ-150W Classifiers

Classifiers

Mobile Tyre Shredder

Mobile Tyre Shredder