Trommels

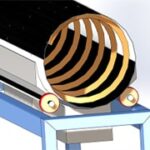

Brentwood offers a range of trommel screens primarily for use in the Recycling and Solid Waste industries. Screens using full steel plate screen mediums available. Drives can be electric or hydraulic and the screens can be supplied with inlet feeders if required. We have a range of standard designs available and we will manufacture custom sizes and configurations according to your requirements.

Brentwood trommels include advanced features such as :

– Dual drives

– Ramp start controls providing easy starting loaded and in wet conditions

– Solid rubber wheels for maximum drive friction in wet conditions

– Brushes for cleaning

– Operator protection

– Walkways for maintenance and operators

– Centre support wheels where required

– Screens easily removable

Options available with Brentwood Trommels:

– Screen – perforated rolled metal plate 10mm thick (typically for C&D applications)

– Internal screw in lieu of lifter beams

– Bag breakers (typically for MSW applications where plastic bags need to be opened)

– Bolt in screen sections (typically used where screen hole sizes may need to be changed)

– Elevated walkway on one or both sides with ladder access (for maintenance and cleaning)

– Cleaning brushes (typically for compost applications to keep drum holes clear)

– Chain drive in lieu of friction drive wheels (typically for C&D applications)

– Bottom chute for discharge for fines onto a conveyor

– End chute for oversize discharge onto a conveyor

– Dust covers with access doors

Standard Brentwood Trommel Sizes

We have a range of standard trommel sizes and designs which are listed below, but more often than not, what is required is a customised solution. If what you are looking for is not in the table below, then call us to discuss a customised design. We will need to know details about your material, the required screening fractions, the required throughput rate, and conditions at the installation site so that we can prepare a customised trommel design.

| Model | Diameter (m) | Length (m) | Power (kW) | Capacity (m3/hr ) | Capacity (t/hr) |

|---|---|---|---|---|---|

| BT10/2.5 | 2.5 | 10 | 15 | 61 | 30 |

| BT8/2.5 | 2.5 | 8 | 10 | 61 | 30 |

| BT10/2 | 2 | 10 | 10 | 48 | 24 |

| BT8/2 | 2 | 8 | 7.5 | 48 | 24 |

| BT6/2 | 2 | 6 | 5.5 | 48 | 24 |

| BT10/1.5 | 1.5 | 10 | 7.5 | 34 | 17 |

| BT8/1.5 | 1.5 | 8 | 5.5 | 34 | 17 |

| BT6/1.5 | 1.5 | 6 | 5.5 | 34 |

Note: capacity based on material with a bulk density of 500kgs/m3

Learn More About Trommels

Learn more about the features of our trommels and the factors that influence trommel design on our Trommels 101 page.