The Technology

Patented technology, exceptional capabilities.M&J Recycling manufactures heavy-duty industrial shredders that feature patented cutting table and rotating knife designs that set them in a class of their own. The entire basic principle is protected by worldwide patents, as are several specific design features.

Exceptionally Durable

All M&J Recycling shredders have an exceptionally large shredding zone that makes it easy to deal with over-size items and to prevent bulky material bridging. Openings between the counter knives make sure sand, gravel, etc pass through easily without causing unnecessary wear.

The large, rotating knives and the counter knives are all made from 500BHN abrasion resistant steel plate. This material is exceptionally wear resistant, making sure the knives have the longest possible service life.

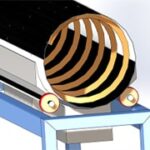

The knives are solidly welded onto the shafts, making M&J Recycling shredders extremely robust, capable of withstanding impacts from any items that simply cannot be shredded. There are no bolts, bearings or adjustable parts anywhere in the cutting area—which significantly cuts down on the need for cleaning and service.

The shafts can turn in both directions with full torque, and can operate asynchronously. This provides greater capacity and less risk of tangling, reduces bridging and spreads the wear evenly on both rotating and counter knives.

Self Cleaning

A special “self-cleaning” system makes sure M&J Recycling shredders automatically reverse their direction of rotation at pre-programmed intervals. As a result, the shredder loosens any material on the shaft and “cleans” the cutting table—also helping prevent unnecessary wear.

Power House

The rotating shafts on M&J Recycling shredders are powered by specially configured hydrostatic drives. These take the mechanical rotary output of the diesel or electric power pack and convert it into hydraulic power. This is then converted back to mechanical power to rotate the shafts. Such hydrostatic drives provide very high shredding power even at low rotating speeds, and are highly reliable even when processing heavy loads.

Intelligently Controlled

All the main functions are monitored and controlled by service-friendly PLCs equipped with intelligent software that automatically adjusts operating profiles to match specific types of input flows. This is supplemented by an Anti Jam System (AJS) that protects both cutting tools and power pack from unnecessary damage. The advanced control electronics make it easy to link M&J Recycling shredders to centralized surveillance facilities and control rooms.

Modular Design

All M&J Recycling shredders feature a modular design that ensures effective upgrade paths and highly cost-effective service life extensions. Changing shafts is rapid and straightforward, and it’s easy to swap out the entire cutting table should your shredding requirements change over time.

Downstream Benefits

The advantages of M&J Recycling shredders aren’t limited to the cutting table. In addition to maximum performance in terms of capacity and grain size, the shredding process is designed to ensure consistently even distribution of material on the conveyor after shredding.