The solution for effective and consistent sizing of soft offal for abattoir and rendering applications

Traditional methods of reducing the particle size of soft offal material from abattoirs involve the use of disc hashers and hoggers. Both of these methods produce inconsistent particle sizing and have poor cutting efficiency resulting in large amounts of separated fat particles (“pea fat”) being generated and lost to the effluent system. Poor cutting efficiency and inconsistent particle size increase cooking times and when bone in material is mixed with soft offal for rendering, the softs can be overcooked resulting in increased fines and increased F.F.A (free fatty acids).

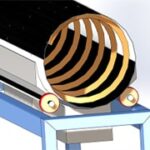

By using a Brentwood Gut Cutter, a consistently sized material is produced and fat losses are minimised therefore increasing the efficiency of downstream processes. The high torque/ low-speed design increases cutting efficiency, reduces power requirements, and reduces maintenance costs. The design of the machine is robust so that any metal items such as hooks are able to be passed through the shredder with minimal damage. Larger unshreddable items will activate the overload back off function enabling an alarm to be sent to the operator and the unshreddable item removed.

These units can be easily cleaned with a high-pressure hose and the hot-dipped galvanised finish ensures a long cutting chamber life. These units were developed in conjunction with the CSIRO (Commonwealth Scientific and Industrial Research Organisation) to increase the efficiency of the Australian Abattoir Industry and have been proven under the most demanding conditions in hundreds of locations throughout Australia, New Zealand, and overseas (see CSIRO report A-89)