The MG Recycling Cable Separation Machine Range

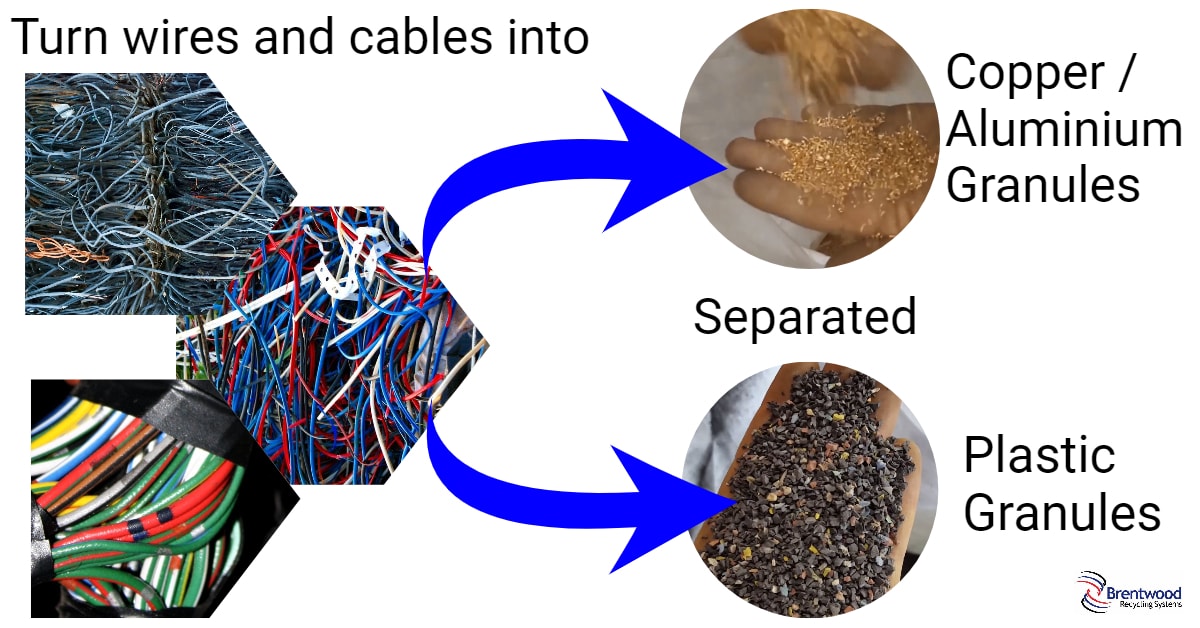

An MG Cable Separation Machine takes the core items utilised in full-sized cable separation plants and combines them in a small footprint machine.

These items include:

- granulator

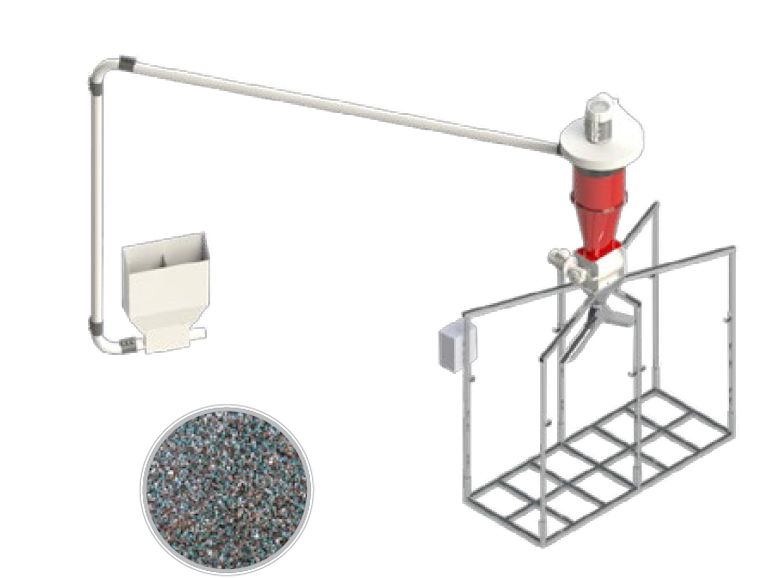

- densimetric separator

- air transport and dust filter systems.

- central electrical controls

Each machine in the range has been designed around a capacity of cable processing. The smallest model, the Monster EVO has a maximum cable processing capacity of up to 100kg per hour. This stretches up to 2000kg per hour in our largest model, the MG 610 VZT.

| Model | Max Production Rate (kg/hr) | POWER (kW) | Dimensions W x D x H (m) |

|

|---|---|---|---|---|

| Monster EVO Monster EVO T | 100 | 5 (Monster EVO) 7.5 (Monster EVO T) | 1.6 x 1.4 x 2.1 |

| MG 150 | 250 | 22.5 | 2.95 x 1.3 x 2.8 |

| MG 220 | 400 | 43 | 3.55 x 1.4 x 3.15 |

| MG 220 VZT | 500 | 60.5 | 3.3 x 4.7 x 4.3 |

| MG 380 VZT | 1000 | 94 | 3.7 x 5.1 x 4.3 |

| MG 610 VZT | 2000 | 75 | 3.5 x 6.8 x 4.4 |

As standard, the machines are designed to be fed by hand. Handfeeding the machines is a great way to get started with cable separation.

When dealing with higher volumes of cables, automation and easier loading in a plant format helps to keep up with the material throughput requirements.