| SpecificationRotor Drive Motor | 55 | kw | 4 pole IP55Fully Enclosed, Fan cooled |

| Full Load current | 92 | amps | |

| Starting current | 92 | amps | Star / delta start |

| Overload Current | 184 | amps | (Overload current level machine is stopped) |

| Voltage | 415 | Volts | |

| Frequency | 50 | Hz | |

| | | |

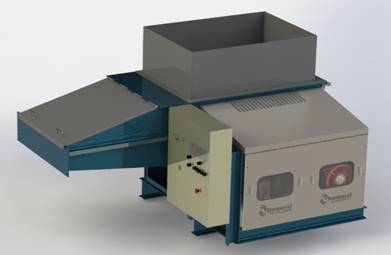

| Cutting Chamer | 1250 | mm | wide |

| 1800 | mm | long (hopper opening) |

| | | |

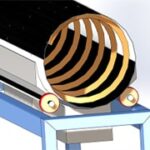

| Rotor | 444 | mm | diam over cutters |

| 90 | RPM | Solid high tensile semi-killed carbon steel, |

| | | machined gooves with machined |

| | | tool holders welded into rotor |

| | | |

| Cutting Knives | H13 | Tool steel | through hardened to approx. 52 Rc. Bolt in replacable and rotateable to provide 4 cutting tips |

| Qty (upto ) | 128 | cutters | |

| 30 | mm | square |

| | | |

| | | |

| Fixed Cutting Blade | H13 | Tool steel | through steel hardened to approx. 52 Rc, fixed by bolts Replacable and rotatable to provide 2 cutting edges |

| | | |

| Secondary fixed bladeRotor | H13 | Tool Steel | tool through steel hardened to approx. 52 Rc, fixed by bolts Replacable and rotatable to provide 2 cutting edges |

| | | |

| Screen under cutters | | | Pivoted for maintenance protected by shear pins |

| | | |

| Pusher Platen | | | Hydraulic actuation to automatically cycle in and out while rotor running. Flat top allows loading on top of platern |

| shredding Stroke | 1240 | mm | |

| | | |

| Hydraulics Power | 5.5 | kW | for operation of pusher platern, |

| Double acting solenoid | 24 | VDC | with "soft-shift" valve action |

| Air blast cooler, | | | |

| visual oil level indicator, | | | |

| oil over-temperature switch, | | | |

| ioil tank capacity | 75 | L | |

| | | |

| Electrical Controls | | | Standard Brentwood controls include a Schneider Modicon PLCProvide |

| "Over-current Sensing" function at | 200% | | of full load to shut down rotor |

| "Under-current Sensing" function | | | to enable pusher platen to stop and reverse direction, to assist material bridging and blockages |

| "Jam Over-time" function | | | to shut down rotor and move platen to homeposition to enable removal of unshredable material |

| Rotor motion detection and solenoid door lock | | | to ensure safe access to screen and conveyor area. |

| Category 3 Safety rating. | | | |

| | | |

| ConstructionFrame - | AS250 | | mild steel welded fabrication |

| | | |

| Machine weight | 7,500 | kg | (approx - with hopper) |

| | | |

| Discharge | | | Belt Conveyor 400mm wide x 3.0m long |

| | | |

| Machine dimensions | | | |

| Incl Hopper & Conveyor | | | 3670mm long x 4340mm wide x 2360mm high |

| Without hopper or conveyor | | | 3670mm long x 2630mm wide x 2360mm high |

| | | |

| Drive | | | Electric motor via belt driven helical gearbox which is shaft mounted to rotor |

| Rotor speed | 90 | RPM | |

| Fully enclosed with safety cover, | | | Interlocked with safty switches Covers |

| Easy access for maintenance | | | hydraulic power pack, rotor drive motor, belts and gearbox |